Product Information

Which fabric should I choose?

The Fabrics

Nylon

The nylon fabric is engineered to be both light weight and durable. The fabric is constructed of high density polyurethane coated nylon, which is easily inflatable and water repellent. Nylon windsocks work well in mild climates and areas with less wind. Of the three fabric choices, the nylon has the best color retention. The nylon fabric is available in a variety of colors. If you require a color other than the standard international orange, please contact us for a custom quote.

Vinyl

The vinyl fabric has superior visibility due to the vibrant color and reflective nature of the fabric. The vinyl is made of high grade polyester fabric that is double coated with fluorescent vinyl for durability and visibility. Coated vinyl lasts longer than laminated vinyl which can de-laminate over time. Vinyl windsocks work well in coastal areas and harsh climates.

Canvas (Cotton Duck)

The 10.10 oz. cotton army duck is the most heavy-duty fabric that we carry. This fabric has been treated to be water repellent and mold resistant.The canvas is long lasting and works best in areas with very strong winds.

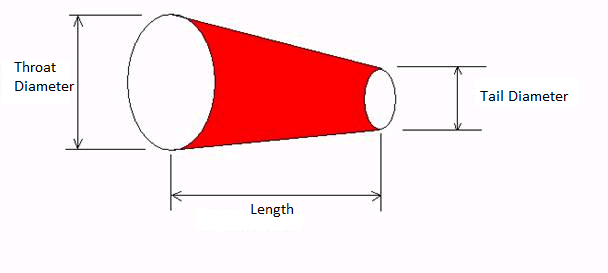

Windsock Construction

All of our windsocks are manufactured in accordance with FAA specifications for fabrication set forth in FAA Advisory Circular No. 150/5345-27D. The 18" diameter x 96" long windsock corresponds to FAA size 1 and the 36" diameter x 144" long windsock corresponds to FAA size 2. Other sizes are manufactured to the same standards as the 18" and 36" windsocks. All windsocks are manufactured and assembled in the United States of America from the best materials available.

The throat end of each windsock is triple hemmed for durability using UV resistant bonded, polyester thread. In addition the throat and tails of our larger windsocks (18” and larger) are reinforced with a triple hemmed band of white cotton duck fabric for additional durability. All windsocks are fitted with weather resistant #2 brass grommets for easy attachment of the windsock to the frame.

How to determine which size replacement windsock is needed

The easiest way to determine the size of the windsock needed is to measure the diameter of the hoop of the windsock frame (see photo of large frame above). Measuring the diameter of the windsock while laying flat will give an incorrect measurement.

Instructions for Mounting 6”, 8", 10" & 12” Windsock Frames

- Place mounting collar onto pole (outer diameter of pole must be less than 3/4” or less than the inner diameter of the coil of the frame) and firmly fasten the collar screws to the pole.

- Place the coiled portion of the frame onto the pole so that it rests on top of the mounting collar.

- The windsock should be tied to the hoop of the frame using weather resistant rope or cable ties provided. Note: Our windsocks are not designed to be threaded onto the hoop of the frame.

Instructions for mounting 18”, 20" & 24” Windsock frames

- Place mounting collar onto pole (outer diameter of pole must be less than 1.5”) and firmly fasten the collar screws to the pole.

- Place frame on pole so that it rests on top of the mounting collar

- Insert steel hoop through holes in the arms of the frame and secure with screw attached to the arm of the frame.

- Windsock should be tied to the frame using weather resistant rope or cable ties. Note: Our windsocks are not designed to be threaded onto the hoop of the frame.

Windsock Maintenance

Check windsocks monthly to make sure they are secured to the windsock frame. Check for tears or holes and replace as needed.

2-3 times per year, we recommend spring and fall at minimum, check that the windsock frame is securely mounted on the pole. Tighten set screws and make sure that the frame can freely rotate around the pole.